Vacuum Thermoformed Packaging Market Evolution: Innovation, Automation, and Sustainability Define the Future

Theory-driven insights reveal how innovation, automation, and sustainability will shape vacuum thermoformed packaging growth.

NEWARK, DE, UNITED STATES, August 11, 2025 /EINPresswire.com/ -- The growth of the vacuum thermoformed packaging market share analysis is not just a numerical forecast — it is the manifestation of deeper industrial trends converging into a clear trajectory. Understanding this market means understanding the theory of how cost pressures, performance requirements, regulatory shifts, and technological innovation interact to redefine packaging’s role in global supply chains.

The Economics of Lightweight, High-Barrier Packaging

The first principle driving expansion is economic efficiency. Vacuum thermoformed packaging offers a rare combination: low material usage without sacrificing strength or barrier protection. This allows manufacturers to reduce production costs while enhancing product longevity — a balance that becomes increasingly critical as margins tighten across industries.

The food & beverage sector’s preference for vacuum-sealed, tamper-evident formats aligns perfectly with this economic logic. Medical applications amplify the need for contamination resistance, while electronics demand secure, custom-fit trays to avoid costly damage. Industrial users—especially in automotive and precision components—turn to heavy-duty thermoformed designs to safeguard products in transit.

Market Consolidation as a Function of R&D Investment

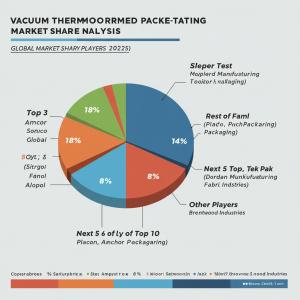

The market’s fairly consolidated structure can be explained through the theory of competitive advantage in capital-intensive industries. Tier 1 leaders — Amcor, Sonoco Products Company, and Berry Global — hold 36% of the market because their continuous investment in advanced thermoforming techniques, automation, and global distribution creates high barriers to entry.

Meanwhile, Tier 2 companies such as Placon, Anchor Packaging, and Display Pack hold 33% by serving niche but high-value markets with tailored solutions. Tier 3’s 31% share, comprised of regional specialists, reinforces the principle that adaptability and customization can offset smaller scale in targeted segments.

Vendor performance benchmarking reflects this hierarchy:

- Top 3: 18% share.

- Rest of Top 5: 10%.

- Next 5 of Top 10: 8%.

Innovation Cycles Driven by Material Science

A recurring theme in this market is the link between material innovation and competitive positioning. Advances in recyclable materials, multi-layer high-barrier films, and custom-molded designs create product differentiation that directly drives market share.

Recent innovations follow this cycle:

- Amcor’s 100% recyclable thermoformed solution (March 2024).

- Sonoco’s lightweight, high-barrier medical packaging (August 2023).

- Berry Global’s tamper-proof, antimicrobial designs (May 2024).

- Placon’s medical-grade expansion (November 2023).

- Anchor Packaging’s temperature-resistant food containers (February 2024).

The theory here is clear: sustained innovation in function + sustainability produces long-term growth and brand authority.

Automation as a Deflationary Force

Automation is not just about replacing labor — it’s about compressing production cycles and reducing variability, effectively acting as a deflationary force on production costs. Manufacturers are integrating:

- AI-driven quality control for precision.

- Predictive analytics to reduce waste.

- Digital twin technology for operational forecasting.

- Predictive maintenance to minimize downtime.

This suggests a future where per-unit costs continue to drop while output consistency rises — a critical advantage in markets where packaging integrity is a core value proposition.

Regional Growth Patterns as a Function of Industrial Structure

Asia-Pacific’s leadership in demand growth aligns with economic geography theory: regions with rapid industrialization and manufacturing diversity adopt scalable, cost-efficient packaging faster. Conversely, North America and Europe shape the market through regulatory and sustainability leadership, forcing global suppliers to meet higher environmental and compliance standards.

This dual dynamic ensures that volume growth is concentrated in Asia-Pacific while technical and regulatory leadership remains strong in Western markets.

Strategic Collaboration as the Next Growth Lever

The next phase of competitive advantage may be defined by cross-supply-chain partnerships. By aligning material suppliers, technology developers, and packaging manufacturers, the industry can compress innovation cycles, lower costs, and scale sustainable solutions faster.

Key strategic recommendations for technology providers include:

- Automation Leadership – Deploy AI-enabled systems for precision manufacturing.

- Material Innovation – Focus on recyclable and bio-based solutions to meet global standards.

- Customization at Scale – Create modular designs adaptable across industries.

- Supply Chain Integration – Partner across tiers to capture new efficiencies.

Request Vacuum Thermoformed Packaging Market Share Analysis Draft Report: https://www.futuremarketinsights.com/reports/sample/rep-gb-21199

For more on their methodology and market coverage, visit! https://www.futuremarketinsights.com/about-us

Smart Packaging as a Functional Evolution

The integration of smart sensors into thermoformed packaging marks a shift from passive containment to active product monitoring. Real-time tracking of seal integrity and contamination risk will become a differentiator in high-value applications such as medical and electronics.

When combined with AI-driven process optimization, these features transform packaging from a cost center into a value-adding asset, aligning with broader trends in Industry 4.0 manufacturing.

Sustainability as an Economic Imperative

The final, and perhaps most transformative, principle is that sustainability is no longer a compliance checkbox — it is a profitability driver. Biodegradable and recyclable monomaterials not only meet regulatory requirements but also appeal to eco-conscious consumers and corporate ESG goals.

As manufacturers adopt sustainable materials and optimize design for recyclability, they create cost savings in raw material sourcing, waste management, and potential tax incentives.

Related Reports:

Mattress And Furniture Bags Market: https://www.futuremarketinsights.com/reports/mattress-and-furniture-bags-market

Breather Bags Market: https://www.futuremarketinsights.com/reports/breather-bags-market

Lip Care Packaging Market: https://www.futuremarketinsights.com/reports/lip-care-packaging-market

Editor’s Note:

This release is based exclusively on verified and factual market content derived from industry analysis by Future Market Insights. No AI-generated statistics or speculative data have been introduced. This press release highlights significant shifts in the Vacuum Thermoformed Packaging Market Share Analysis, which is experiencing a pivotal change driven by consumer demand for healthier, more transparent products.

Rahul Singh

Future Market Insights Inc.

+18455795705 ext.

email us here

Legal Disclaimer:

EIN Presswire provides this news content "as is" without warranty of any kind. We do not accept any responsibility or liability for the accuracy, content, images, videos, licenses, completeness, legality, or reliability of the information contained in this article. If you have any complaints or copyright issues related to this article, kindly contact the author above.