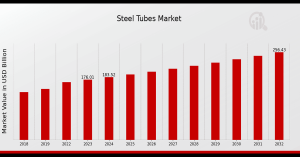

Steel Tubes Market Projected to Grow at 4.27% CAGR, Hitting USD 256.3 Billion by the Year 2032

Steel tubes market thrives with growth in construction, oil & gas, automotive, and mechanical applications across global industries

The steel tubes market supports industries with strength and precision, delivering versatile solutions for construction, energy, automotive, and engineering needs.”

NEW YORK, NY, UNITED STATES, August 13, 2025 /EINPresswire.com/ -- Steel Tubes Market Overview— MRFR

As per MRFR analysis, the Steel Tubes Market Size was estimated at 168.8 (USD Billion) in 2022.The Steel Tubes Market Industry is expected to grow from 176.01(USD Billion) in 2023 to 256.3 (USD Billion) by 2032. The Steel Tubes Market CAGR (growth rate) is expected to be around 4.27% during the forecast period (2024 - 2032).

The steel tubes market is a vital segment of the global steel industry, serving a wide array of applications in construction, automotive, oil and gas, water transportation, and industrial machinery. Steel tubes are preferred for their durability, tensile strength, corrosion resistance (especially when alloyed or galvanized), and adaptability in both structural and fluid-conveyance roles. They are manufactured in various shapes—circular, square, and rectangular—and can be seamless or welded, depending on the intended use.

In recent years, global infrastructure expansion, urbanization, and the rising demand for energy have significantly boosted steel tube consumption. Additionally, the emphasis on high-strength, lightweight materials in automotive and mechanical industries has driven innovation in manufacturing processes and product design.

Get Free Sample PDF Brochure: https://www.marketresearchfuture.com/sample_request/22690

Key Companies in the Steel Tubes Market Include:

MarubeniItochu Steel Inc.

Hyundai Steel Company

Gerdau S.A.

Voestalpine AG

Vallourec

JFE Shoji Trade Corporation

Tenaris

Metal One Corporation

TMK

JSW Steel Ltd.

JFE Steel

SSAB

Welspun Corp Ltd

Kobe Steel, Ltd.

Nippon Steel Sumitomo Metal Corporation

Market Dynamics

The steel tubes market operates in a complex interplay of supply chain, raw material prices, technological capabilities, and end-user demand. Steel tube production relies heavily on steel prices, which fluctuate based on iron ore availability, coking coal costs, and geopolitical trade policies. Demand surges during periods of construction booms or energy sector expansion, while economic slowdowns can create oversupply and pricing pressures. The market is also influenced by environmental regulations, particularly those aimed at reducing carbon emissions in steel manufacturing.

Technological progress in electric arc furnaces (EAFs), continuous casting, and precision welding has enhanced efficiency and quality in steel tube production. Competition is intense, with numerous global and regional players striving to improve cost efficiency, product customization, and distribution networks. Strategic collaborations between manufacturers and end-users, as well as integration of digital supply chain management, are becoming increasingly important for maintaining market share.

Drivers

Several factors are driving the steel tubes market:

Infrastructure Development: Rapid urbanization and infrastructure modernization projects worldwide have created a sustained demand for structural steel tubes in bridges, buildings, and transportation systems.

Energy Sector Growth: Oil and gas exploration, pipeline projects, and renewable energy facilities require large volumes of specialized steel tubes capable of withstanding high pressure and extreme temperatures.

Automotive and Transportation Needs: Lightweight yet strong steel tubes are essential for vehicle frames, exhaust systems, and railway applications, aligning with the industry’s push for fuel efficiency.

Water Management and Sanitation: The increasing need for clean water supply and wastewater treatment systems has stimulated demand for corrosion-resistant steel pipes and tubes.

Industrial Expansion: The rise in manufacturing activities in sectors such as petrochemicals, food processing, and heavy machinery contributes to steady consumption.

Buy Now Premium Research Report: https://www.marketresearchfuture.com/checkout?currency=one_user-USD&report_id=22690

Technological Advancements and Innovation

Innovation in the steel tubes market has centered on enhancing strength-to-weight ratios, corrosion resistance, and precision engineering. Key advancements include:

High-Strength Low-Alloy (HSLA) Tubes: Development of steels with microalloying elements like vanadium and niobium provides higher strength without excessive weight.

Advanced Welding Techniques: Laser welding and submerged arc welding have improved seam quality in welded tubes, bringing performance closer to seamless tubes while lowering costs.

Corrosion-Resistant Coatings: Galvanization, epoxy lining, and advanced powder coatings extend service life, particularly in marine and underground applications.

Automation and Smart Manufacturing: Integration of Industry 4.0 technologies, including AI-driven quality control and real-time production monitoring, increases consistency and reduces defects.

Green Steel Production: Electric arc furnaces using scrap steel, along with carbon capture and utilization (CCU) technologies, are paving the way for environmentally friendly steel tubes.

Steel Tubes Market Segmentation Insights

Steel Tubes Market Product Type Outlook

Seamless Steel Tubes

Welded Steel Tubes

Other Steel Tubes

Steel Tubes Market Application Outlook

Automotive

Construction

Oil and Gas

Industrial Machinery

Other Applications

Steel Tubes Market Material Outlook

Carbon Steel

Stainless Steel

Alloy Steel

Other Materials

Steel Tubes Market Production Process Outlook

Hot Rolling

Cold Rolling

Extrusion

Other Production Processes

Browse In-depth Market Research Report: https://www.marketresearchfuture.com/reports/steel-tubes-market-22690

Challenges and Market Constraints

Despite steady growth, the steel tubes market faces several challenges:

Raw Material Price Volatility: Fluctuations in iron ore and coal prices can disrupt production costs and profitability.

Environmental Regulations: Stringent emission control laws can increase operational costs for steel manufacturers.

Competition from Alternative Materials: Aluminum, composites, and plastic pipes are gaining popularity in certain applications due to lighter weight or lower cost.

Global Trade Policies: Tariffs, anti-dumping duties, and import/export restrictions can alter supply chains and pricing structures.

Economic Uncertainty: Slowdowns in construction or oil prices can cause demand swings, impacting production planning.

Energy Costs: Steel production is energy-intensive, and rising energy prices directly affect manufacturing expenses.

Future Outlook

The steel tubes market is expected to witness sustained growth over the next decade, driven by global infrastructure expansion, industrial modernization, and the ongoing energy transition. Emerging economies will remain key growth engines due to their large-scale construction projects, manufacturing expansion, and rising energy needs. Developed markets will focus on high-performance, specialized tubes and sustainable production methods.

Technological advancements will continue to reshape the market, with automation, green steel initiatives, and enhanced coatings improving product performance and environmental compliance. Demand from renewable energy sectors—such as wind and solar power—will create new opportunities for corrosion-resistant and high-strength steel tubes.

However, market players will need to navigate challenges related to environmental regulations, raw material price swings, and competition from alternative materials. Strategic investments in research and development, recycling processes, and digital supply chain systems will be critical for staying competitive.

Overall, the steel tubes market is set for a future of steady, innovation-driven growth, with sustainability and performance optimization at its core.

More Related Reports:

self contained breathing apparatus market: https://www.marketresearchfuture.com/reports/self-contained-breathing-apparatus-market-12109

milk tank cooling system market: https://www.marketresearchfuture.com/reports/milk-tank-cooling-system-market-12110

plastic extrusion machine market: https://www.marketresearchfuture.com/reports/plastic-extrusion-machine-market-12111

Laundry folding machine Market: https://www.marketresearchfuture.com/reports/laundry-folding-machine-market-12123

Additive Manufacturing Machine Market: https://www.marketresearchfuture.com/reports/additive-manufacturing-machine-market-12188

Engine Bearings Market: https://www.marketresearchfuture.com/reports/engine-bearings-market-12335

Food Processing Machinery Market:https://www.marketresearchfuture.com/reports/food-processing-machinery-market-12364

Cold Chain Equipment Market https://www.marketresearchfuture.com/reports/cold-chain-equipment-market-12365

About Market Research Future

At Market Research Future (MRFR), we enable our customers to unravel the complexity of various industries through our Cooked Research Report (CRR), Half-Cooked Research Reports (HCRR), Raw Research Reports (3R), Continuous-Feed Research (CFR), and Market Research Consulting Services. The MRFR team have a supreme objective to provide the optimum quality market research and intelligence services for our clients. Our market research studies by Components, Application, Logistics and market players for global, regional, and country level market segments enable our clients to see more, know more, and do more, which help to answer all their most important questions.

Market Research Future

+ +1 8556614441

email us here

Market Research Future

Legal Disclaimer:

EIN Presswire provides this news content "as is" without warranty of any kind. We do not accept any responsibility or liability for the accuracy, content, images, videos, licenses, completeness, legality, or reliability of the information contained in this article. If you have any complaints or copyright issues related to this article, kindly contact the author above.