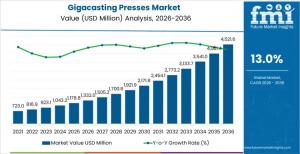

Gigacasting Presses Market to Surpass USD 4.5 Billion by 2036 on EV Manufacturing Transformation

Gigacasting presses market grows at 13% CAGR through 2036 as OEMs adopt large structural castings for EV efficiency.

NEWARK, DE, UNITED STATES, January 16, 2026 /EINPresswire.com/ -- Gigacasting Presses Become Central to Next-Generation Automotive Manufacturing

The global Gigacasting Presses Market is gaining strategic importance as automotive OEMs redesign vehicle platforms around fewer, larger structural components. According to recently updated market analysis, the market is projected to grow from USD 1,332.0 million in 2026 to USD 4,521.6 million by 2036, reflecting a strong CAGR of 13.0% over the forecast period. This growth is closely tied to the rapid scale-up of electric vehicle (EV) production and the industry-wide push toward manufacturing simplification.

Unlike conventional equipment markets, gigacasting presses are constrained by high equipment concentration and limited global capacity for ultra-large tonnage systems. Only a small group of suppliers can deliver presses above 6,000 tons, making procurement decisions long-term and strategic rather than opportunistic.

OEMs Shift from Part Assembly to Structural Consolidation

Automotive manufacturers are increasingly using gigacasting to replace dozens of stamped and welded parts with single-piece aluminum castings. This approach delivers measurable benefits across cost, speed, and quality.

Key manufacturing advantages driving adoption include:

- Reduction in tooling count and body shop complexity

- Shorter assembly cycles and faster model launches

- Improved dimensional accuracy and reduced tolerance stack-up

- Lower per-vehicle manufacturing and labor costs

These advantages are particularly valuable for EV platforms, where lightweight structures directly influence range, efficiency, and total cost of ownership.

Subscribe for Year-Round Insights → Stay ahead with quarterly and annual data updates:

https://www.futuremarketinsights.com/reports/sample/rep-gb-31435

Capital Efficiency and Reliability Drive Press Selection

Purchasing decisions in the gigacasting presses market are increasingly performance-driven. OEMs and Tier-1 suppliers assess presses not only on tonnage capacity, but also on operational stability and integration potential.

Critical evaluation criteria include:

- Locking force stability at ultra-high tonnage

- Shot size capability and cycle time consistency

- Compatibility with automated trimming and inspection systems

- Predictable uptime and long-term service support

Because a single gigacasting press can account for a large share of body-in-white output, downtime risk is a major concern. Suppliers demonstrating proven durability, rapid die-change capability, and strong regional service presence are gaining preferred supplier status.

High-Pressure Die-Casting Dominates Process Selection

High-pressure die-casting (HPDC) accounts for approximately 74% of the gigacasting presses market, supported by its scalability and production efficiency. HPDC enables rapid filling of large molds while maintaining consistent mechanical properties and surface finish.

Rear underbody structures lead application demand, representing about 38% of total market share. These components offer the highest consolidation benefits, as they can replace numerous welded assemblies while maintaining structural integrity and crash performance.

Regional Growth Patterns Reflect EV Investment Cycles

Market growth varies significantly by region, shaped by EV manufacturing scale and investment in advanced foundry infrastructure.

Country-level growth outlook highlights:

- China: Leading growth with a projected CAGR of 12.2%, driven by large-scale EV production and domestic press manufacturing

- Brazil: CAGR of 11.8%, supported by modernization of automotive plants and rising EV adoption

- United States: CAGR of 10.7%, with gigacasting increasingly integrated into high-volume EV programs

- Germany: CAGR of 10.6%, focused on precision engineering and platform transitions

- South Korea: CAGR of 10.2%, aligned with next-generation EV manufacturing strategies

Across regions, OEMs are prioritizing localized service, faster commissioning, and reduced exposure to cross-border logistics disruptions.

Supply Chain and Capital Constraints Shape Market Dynamics

Despite strong demand, market expansion is moderated by high capital requirements and technical complexity. Gigacasting presses—often ranging from 4,000 to over 9,000 tons—require significant upfront investment, alongside custom die tooling, advanced thermal management, and skilled commissioning teams.

Additional constraints include:

- Long manufacturing lead times due to custom press design

- Dependence on specialized aluminum alloys and large-format dies

- Limited availability of experienced die-casting technicians

As a result, press procurement is closely linked to long-term production planning and supplier alignment rather than short-term capacity expansion.

Competitive Landscape Centers on Engineering Depth and Scale

Competition in the gigacasting presses market is defined by clamping force scalability, automation integration, and service capability. Global leaders such as IDRA Group and Bühler focus on ultra-large press platforms optimized for single-piece vehicle structures. Japanese and European manufacturers emphasize mechanical rigidity and long-term reliability, while Chinese suppliers are intensifying competition through cost-performance positioning and rapid scale-up.

Strategic Outlook

Gigacasting presses are increasingly viewed as foundational infrastructure for next-generation automotive manufacturing. As EV platforms scale and vehicle architectures consolidate, press selection will continue to influence cost structure, production resilience, and competitive positioning.

Get data that aligns with your strategic priorities — ask for report customization today:

https://www.futuremarketinsights.com/customization-available/rep-gb-31435

Related Reports

Military Parachute Market – https://www.futuremarketinsights.com/reports/military-parachute-market

Automated Parcel Delivery Terminals Market – https://www.futuremarketinsights.com/reports/automated-parcel-delivery-terminals-market

Automatic Checkweigher Market – https://www.futuremarketinsights.com/reports/automatic-checkweigher-market

Have a specific Requirements and Need Assistant on Report Pricing or Limited Budget please contact us - sales@futuremarketinsights.com

About Future Market Insights (FMI)

Future Market Insights, Inc. (FMI) is an ESOMAR-certified, ISO 9001:2015 market research and consulting organization, trusted by Fortune 500 clients and global enterprises. With operations in the U.S., UK, India, and Dubai, FMI provides data-backed insights and strategic intelligence across 30+ industries and 1200 markets worldwide.

Contact Us:

Future Market Insights Inc.

Christiana Corporate, 200 Continental Drive,

Suite 401, Newark, Delaware - 19713, USA

T: +1-347-918-3531

Why FMI: https://www.futuremarketinsights.com/why-fmi

For Sales Enquiries: sales@futuremarketinsights.com

Website: https://www.futuremarketinsights.com

LinkedIn| Twitter| Blogs | YouTube

Sudip Saha

Future Market Insights Inc.

+1 347-918-3531

email us here

Legal Disclaimer:

EIN Presswire provides this news content "as is" without warranty of any kind. We do not accept any responsibility or liability for the accuracy, content, images, videos, licenses, completeness, legality, or reliability of the information contained in this article. If you have any complaints or copyright issues related to this article, kindly contact the author above.